There is no doubt that glass has unique properties and advantages compared to materials such as metals and polymers: it is optically transparent, resistant to thermal shocks, abrasion and scratches, it is biocompatible by nature, chemically stable and electrically insulating, but what is less evident is that, it has fantastic elasticity properties and a high failure strength after chemical treatment.

Glass has therefore become a widespread material in horology and fine mechanics, whereas its tribological behavior, combined with cutting-edge three-dimensional structuring capabilities, have persuaded leading brands of the Haute Horlogerie to adopt FEMTOprint’s industrialized, accurate and complete microfabrication platform to produce novel watch movements, dials, actuators, balance wheels and time indicators.

Ulysse Nardin, a luxury Swiss watch manufacturer, has been at the pioneering of watchmaking since its foundation in 1846. After a successful splash in 2017 with the release of the timepiece InnoVision Two (femtoprint.ch/news-innovision2) – a concept watch that caught the attention of enthusiast for the number of impressive innovations (among them the self-winding mechanism, the oscillator, the three-dimensional glass minute hand and the glass bridge with integrated shock protection for the balance wheel) – Ulysse Nardin has now launched a new exceptional timepiece : the new FREAK neXt watch. It is the current quintessence of all the technical and watchmaking skills of the Maison Horlogère. This prototype watch, aiming at showcasing Ulysse Nardin’s technological milestone and FEMTOprint’s state-of-the-art microfabrication expertise in glass, unveils a new flying caroussel baguette movement equipped with a 3D-flying oscillator of truly spectacular design.

As a result of the flying tourbillon and the flying anchor escapement, developed in the last 10 years, this new watch is presenting what appears to be the pinnacle of a paradigm shift in mechanical watchmaking: the new flying oscillator. Based on flexible mechanisms using the elasticity of silicium blades, this oscillating regulating device does away with the central pivot and the oscillator is literally suspended in mid-air. The primary idea of this regulating organ is to completely eliminate the axis of the balance wheel in order to create a virtual pivot point, resulting in the total elimination of friction on the bearings, optimizing the global quality factor and therefore the movement’s energy consumption. This is a radical development that hugely improves the traditional principle of balance spring regulation introduced in the 17th century.

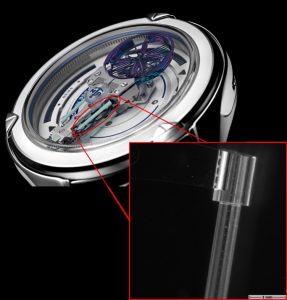

Toying with the limits of the physics of materials, the unlimited design freedom, the unconventional surface smoothness and shape accuracy given by the FEMTOPRINT® technology, the new Freak neXt presents the glass bridge of the baguette movement (the finishing gear train) with a slightly trapezoidal shape inspired by the spaceships from Star Wars. It is framed by four luminescent and transparent glass tubes (FIGURE 1), being each 400 µm in diameter (with inlets of 200 µm) and 8.34 mm in length, filled with Superluminova.

The phosphorescence effect, visible only at night, is given by a strontium aluminate–based, non-radioactive and nontoxic photoluminescent pigment. The tubes are then superposed in a monolithic set of two, suspended on the baguette with a precision of just a few microns, thanks to the sub-microns process resolution that made possible these timepieces.

FIGURE 1: The FREAK next timepiece with 3D glass tubes for luminescent purpose (Photo credit: Ulysse Nardin/FEMTOprint)

Excavating the material from the tubes, without compromising their robustness, shape accuracy and transparency, has been a major focus during manufacturing.

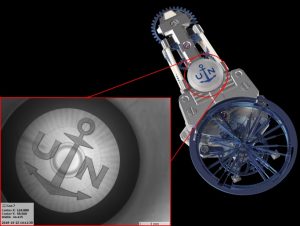

The light generated by the pigments is then enhancing Ulysse Nardin’s logo, revealed in its characteristic marine blue (FIGURE 2) and engraved in the glass lens, to complete the decoration of the baguette movement. This central piece, 5.0 mm in diameter and 1.95 mm in height, exposes all the main challenges of fabricating three-dimensional and monolithic structures in glass: multiple heights (from the lens contour to the trenched logo at the surface, 130 µm to 180 µm deep in the volume), planar and convex shapes with different angles and radius, paintings for decorations, selective surface polishing, combined with tight requirements in the range of a few microns geometrical tolerances and below 20 nm Ra for the surface finishing.

FREAK neXt is an extreme example of how progressive attitudes and advanced laser-based microfabrication technologies can create truly innovative value, on which creativity is pictured in 3D unique timepieces. In this context, the cutting-edge FEMTOPRINT® technology is professionally combining precision manufacturing with high aesthetical characteristics, blending fluidic, optical and mechanical functionalities into single monolithic devices.

FIGURE 2: The FREAK next timepiece with the 3D glass logo-decoration (Photo credit: Ulysse Nardin/FEMTOprint)

Thanks to the core competencies in precision microfabrication services and the world’s most performant and industrialized 3D printing platform for glass microdevices, FEMTOprint is changing the way highly complex microsystems are conceived.

With applications in the area of fine mechanics, photonics, micro-optics, microfluidics and packaging, the FEMTOPRINT® microfabrication platform is fully equipped to provide serial manufacturing of integrated optical circuits (e.g. waveguides and lens), 2D and 3D manufacturing, several glass polishing and hermetic sealing capabilities as well as selective metal structuring processes to create custom-made distinctive glass microdevices.

The maskless and out-of-cleanroom technology, combined with a sub-micron resolution, an aspect ratio of more than one to five hundred, and the ability to process batch wafers up to 200 mm in lateral size and heights up to 12 mm, are just a few advantages. High repeatability, surface finishing and geometrical precision, the absence of stitching or staircase effects, makes it a truly unique technology for a broad range of applications, already certified ISO 13485:2016 for medical devices.

The Ulysse Nardin Freak NeXt is still a concept watch whose revolutionary development might make it into production in a very near future, as the brand declares. As demonstrated in the history of the multiple variations of the Freak’s product family, long traditions in the field of chronometry are accompanied by innovative and radical concepts in design, display and technology, drifted into commercially available products. FEMTOprint is proud to be part of this success and to continue pushing the boundaries of innovation with leading industry partners in the field of watchmaking, medtech, biotech, optics, photonics, automotive, aerospace and electronics.

FIGURE 3: The FREAK next timepiece (Photo credit: Ulysse Nardin)

FEMTOprint goes along with audaciousness minds.

This story was submitted by giulia.bottarini@femtoprint.ch.