Watchmaking is a field where every little innovation counts.

It’s a world where precision and durability are imperative, where every element, no matter how small, plays a crucial role in the overall functioning of the watch. Today, a new era is opening up in this field with the development of a complete lead-free barrel, meeting the strict requirements of the European REACH standard.

As an added bonus, the introduction of the Bioflex barrel spring marks a major step forward in avoiding the potentially harmful use of beryllium.

These innovations have been made possible by the synergies of up to six Acrotec Group companies, under the aegis of Generale Ressorts, which have developed knowledge of the different manufacturing processes and management of machining and decoration tools, guaranteeing the same quality as products made with current materials.

Benefits of lead-free barrels

The introduction of an entirely lead-free barrel offers a host of advantages for the watchmaking industry. Firstly, it enables full compliance with the new European REACH regulations, which aim to restrict the use of hazardous substances in manufactured products.

By eliminating lead from the composition of the barrel, watch manufacturers can guarantee user safety and reduce their ecological footprint. What’s more, lead-free barrels offer greater durability and long-term stability.

Indeed, lead is known for its tendency to oxidize and corrode over time, which can alter the appearance of components. By replacing lead with safer, more durable materials, such as lead-free stainless steel or brass, manufacturers can improve the reliability and longevity of their products.

Finally, this innovation also offers opportunities for differentiation and market positioning.

By offering watches with lead-free barrels, brands can highlight their commitment to quality, safety and technological innovation, which can be a convincing selling point for consumers who are increasingly concerned about the environmental impact of their purchases.

Lead-Free Component Manufacturing Challenges and Innovative Techniques

The transition to lead-free components in the watchmaking industry has not been without technical and logistical challenges.

Eliminating lead from manufacturing materials required a complete overhaul of production processes and the exploration of new techniques to guarantee component quality and performance.

One of the major challenges was to find lead-free alloys offering mechanical properties comparable to those of traditional materials, while maintaining a high level of precision.

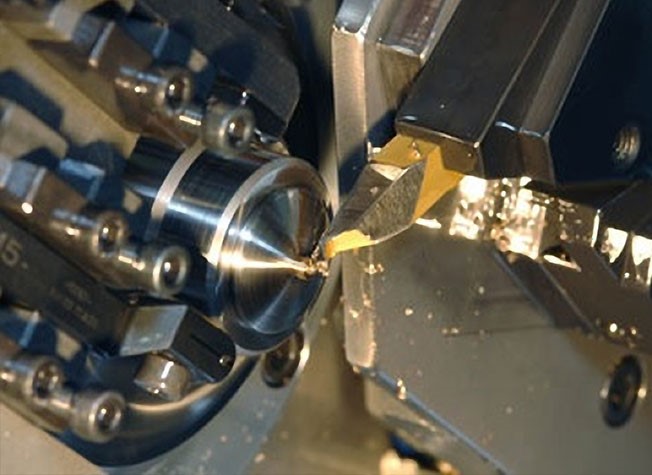

This involved in-depth research and rigorous testing to select the most suitable alloy grades, as well as adapting bar-turning machines and tools to work with these new materials..

In addition, the adaptation of manufacturing processes was essential to ensure the quality and durability of lead-free components.

This included optimizing galvanic treatment undercoats to ensure optimum adhesion, an aesthetic appearance to match current components, and uncompromising corrosion protection.

In the end, thanks to the commitment and expertise of the R&D teams, as well as the synergies between the various Acrotec Group companies, these challenges were successfully overcome.

The manufacture of lead-free components in watchmaking is now a reality, paving the way for a new era of innovation and sustainability in the industry.

Innovation: Bioflex barrel spring

In addition to the development of the lead-free barrel, the introduction of the Bioflex barrel spring marks a significant step forward in modern watchmaking.

Bioflex is an innovative, environmentally-friendly material that is free from beryllium, an element likely to be banned in the future by REACH due to its harmful effects on human health.

Replacing the Nivaflex barrel spring with Bioflex offers several advantages. Bioflex is not only environmentally friendly, but also offers significant technical improvements.

It contributes to improved chronometry, increased power reserve and spring reliability, surpassing Nivaflex in terms of performance and durability.

By adopting the Bioflex barrel spring, watch manufacturers can not only anticipate future regulatory developments, but also reinforce their brand image as responsible and innovative players in the watch industry..

Conclusion

The development of an entirely lead-free complete watch barrel, accompanied by the use of a Bioflex barrel spring, represents a veritable revolution in the watchmaking industry.

In addition to meeting the new requirements of the European REACH standard, these innovations offer tangible benefits in terms of durability, reliability and market differentiation.

By adopting these advances, watch manufacturers can not only guarantee the safety and satisfaction of their customers, but also contribute to the preservation of the environment and the sustainability of their industry.