Showcasing precision watchmaking, the EPHJ trade fair welcomes a panoply of supremely talented subcontractors. Among them is Vuichard SAS, a firm from the Haute-Savoie region close to the Franco-Swiss border.

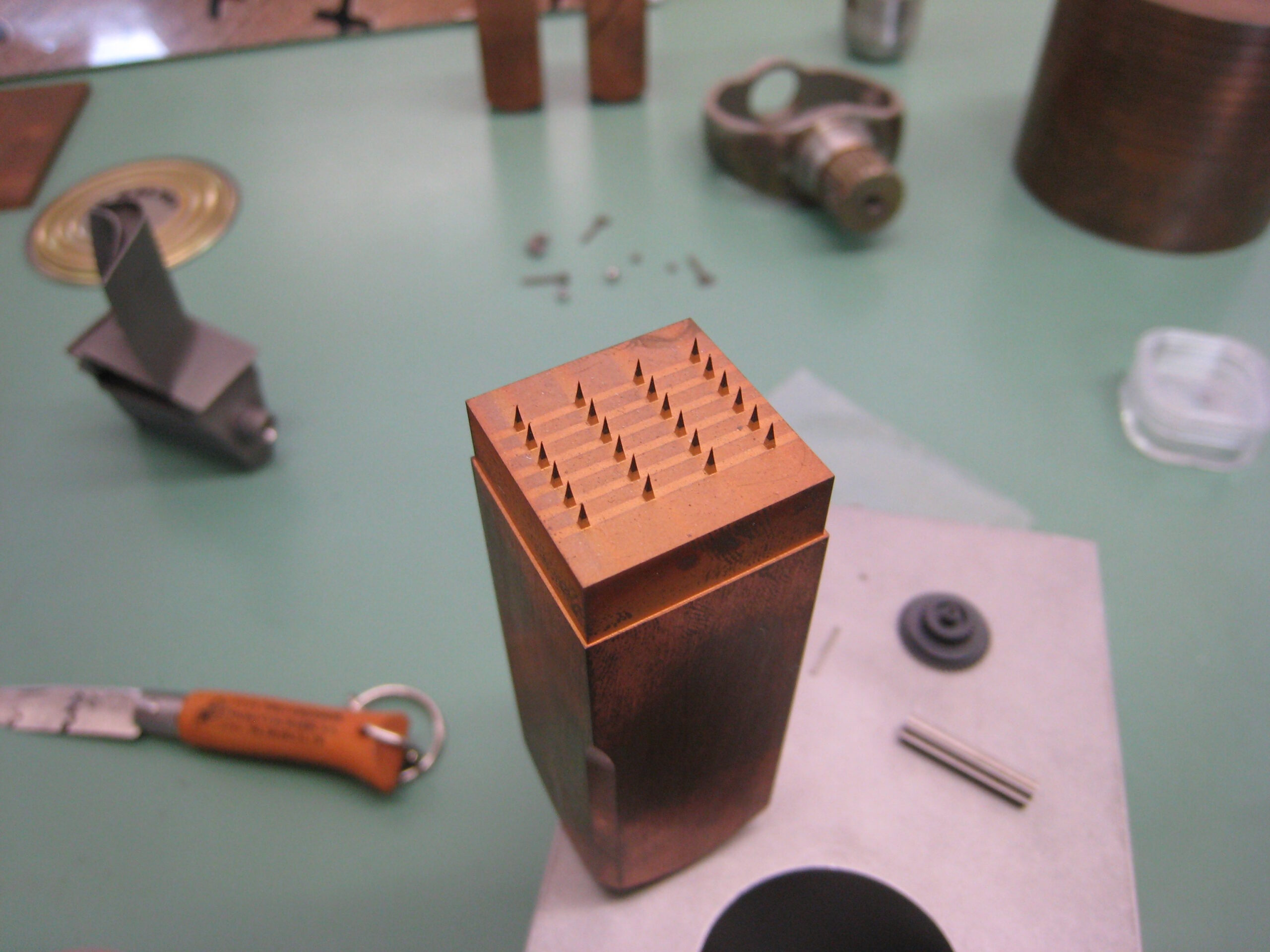

It will be an exhibitor at EPHJ once again in 2025, drawing on expertise gleaned from almost 60 years’ experience in extra-high-precision machining to present some real feats of nanomachining. Visitors will be able to examine samples under a high-power magnifying glass, all produced using one-of-a-kind techniques. The company’s beginnings lie in die-sinking electro-discharge machining (EDM) and wire cutting, as illustrated by its fleet of 10 or so micro-erosion machines, using wire with a minimum diameter of 0.03 mm. Holes can be micro-drilled to diameters as small as 0.025 mm in the die-sinking discharge machining workshop. In 5-axis micro-milling, its Matsuura machining centre – with a 60,000-rpm spindle, 0.1-μm travel and cutters that are at least 0.04 mm in diameter – produces work of unrivalled finesse in steel with a hardness of up to 65 HRC. Micromachining makes up another element of this expertise.

Thanks to the precision of the Matsuura LX-O 5-axis machining centre, precision electrode production allows for die-sinking operations of a quality that would otherwise be impossible to achieve.

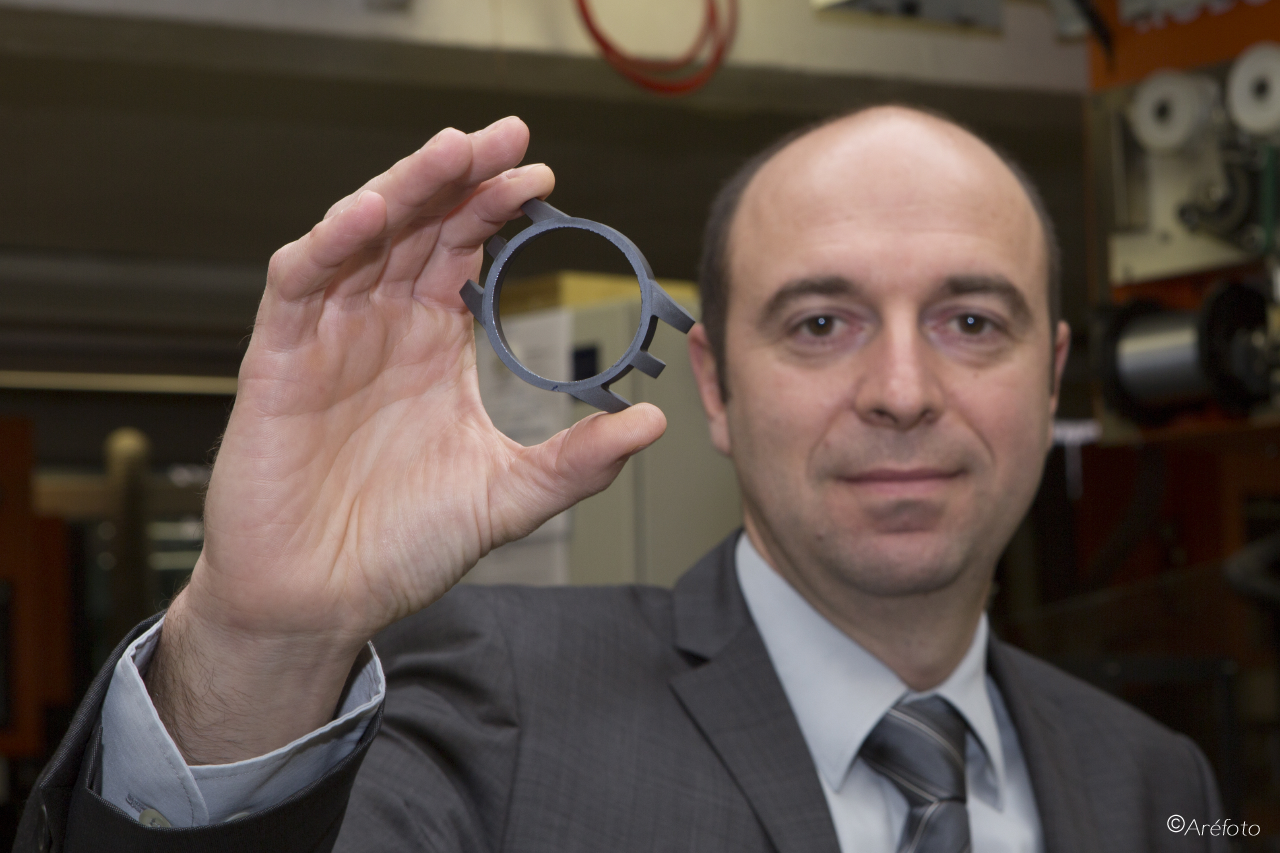

The relevant technologies have contributed to the creation of an outstanding watch, bringing together micro-erosion machines and machining of silicon crystal. As specialists in the seemingly impossible, ceramic parts manufacturer HARDEX and French subcontractor Vuichard rose to the challenges set by the designer. The products of other challenges recently taken on by Vuichard SAS will be on display at its stand in 2025. Like the company itself, here we have a modestly-sized space which will be showcasing some big innovations on a very small scale!

The relevant technologies have contributed to the creation of an outstanding watch, bringing together micro-erosion machines and machining of silicon crystal. As specialists in the seemingly impossible, ceramic parts manufacturer HARDEX and French subcontractor Vuichard rose to the challenges set by the designer. The products of other challenges recently taken on by Vuichard SAS will be on display at its stand in 2025. Like the company itself, here we have a modestly-sized space which will be showcasing some big innovations on a very small scale!

Michel Pech