It is possible to be 75 years old and still have a start-up mindset. DIXI Polytool, a long-established manufacturer of precision tools for watchmaking and other microtechnologies, has just invented a revolutionary miniature milling cutter.

By Joël A. Grandjean

With two patents registered and a trademark, DIXI Cool+, entered in the intellectual property register, the outlook is promising. It’s a safe bet that any milling outfit will want to access the unique convenience offered by this miniature marvel.

All-important cooling liquids

Any milling operation (i.e. machining by chip removal) requires lubricants or cutting fluids. In the past, water was used, but this has now been replaced by specially developed liquids. Such liquids are needed because, when the material being worked comes into contact with the tool that works it, whether made of hard metal or diamond, a lot of heat is generated. This needs to be cooled, both to prevent the cutter from wearing too much and to stop the machined material from melting and deforming.

A way therefore needs to be found for the liquid to spray the point of contact, continuously and abundantly, either by being projected by one or more external jets, or by peripheral spraying via the tool holders or collets. A third option is internal spraying, where the lubricant passes through the tool itself, spurting out at the end or working its way into the flutes when the cutting diameters are greater than 6 millimetres.

Below 6 mm

When the cutting diameter is less than this, things get complicated. It is difficult to get liquids to the cutting edge of tools efficiently. This is where the science of compromise comes in, the main solution being to boost the rotational speed to 8,000 or 10,000 revolutions per minute. The problem is that the external coolant only partially reaches the cutting area since at this speed it is pushed back by the ring of air gyrating around the tool. Consequently, the cutting temperature increases, causing a reduction in the mechanical properties of the tungsten carbide, which in turn shortens the service life of the cutter. Not to mention the chips of material that adhere around the tool and interfere with the smooth running of the milling process, generating unsightly surface finishes and, above all, causing tool breakage.

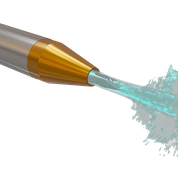

DIXI Cool+ is a game changer. For all those infinitely small machining operations, such as grooving and pocket milling, this invention solves the problem of transporting lubricating liquids to the point of contact. The fluid is guided and then directed as close as possible to the machining area by means of a system of micro-channels running through the tool, which help the liquid transit from the rear to the active part at the front, and also a directional ring which uses clever mathematical formulae to ensure a higher spray power at constant flow.

The benefits of DIXI Cool+

The advantages of this protected invention are not limited to end mills, but extend to ball-nose cutters, thread cutters and through-hole reamers. The benefits are a longer service life for tools and enhanced neatness of the machined material, which allows savings on monitoring costs after the start of operations. And in a high-wage country like Switzerland, that matters!

In terms of micro-milling, DIXI Cool+ ultimately delivers an appreciable gain in productivity. It has come just at the right time, as manufacturers race to miniaturise many mechanisms and devices in all microtechnology sectors, including the medical and dental industries, bar turning, watchmaking, electronics, automotive and aerospace.