Coat-X, a company specialising in thin film encapsulation, has demonstrated that its technology can protect electronic implants for many years – a fine success that rewards all the R&D the company is continuing to carry out at top speed for use in medical applications.

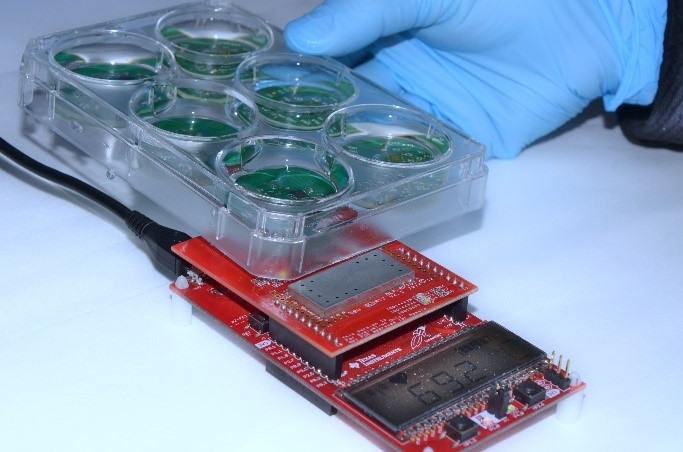

Founded in 2016 and based in La Chaux-de-Fonds, Switzerland, Coat-X is a European leader in parylene-based thin film encapsulation via chemical vapour deposition (CVD). Early on, the company specialised in coating implants and is ISO 13485 certified. These ultra-hermetic coatings are just a few microns thick and conform perfectly to the topography of the substrate, protecting implanted medical devices from the aggressive environment of the human body and enhancing their biocompatibility. In moving beyond simple parylene coatings, Coat-X has also developed unique expertise in the production of multilayers of parylene interspersed with ceramics, a process that makes the coatings approximately four times more hermetic. In partnership with the Wyss research institute in Geneva, Coat-X subjected an electronic implant protected with its coating to accelerated ageing by immersing it in a saline solution. The device was wirelessly monitored round the clock to ensure that it was operating properly. The experiment found that encapsulation gave the implant a service life of more than 10 years. The experiment was then extended with a view to demonstrating a lifespan of more than 20 years.

Characterisation in order to optimise and guarantee quality

Coat-X’s coating know-how is complemented by its expertise in characterisation techniques for hermetic thin films, specifically measuring the permeation of gas molecules such as helium. To this end, Coat-X has developed fully automated instrumentation as well as the relevant test and analysis protocol. This expertise is essential when it comes to optimising the technology for each customer application and guaranteeing coating quality, which is why other innovative techniques for measuring permeability and other key parameters are being developed and will soon be available for the characterisation of thin encapsulation films.

Alongside encapsulation applications, Coat-X has recently innovated in the field of non-fluorinated hydrophobic thin layers applied at low temperature, developing a special process to deposit a very thin, highly water-repellent ceramic coating on all kinds of substrates, such as fabrics and paper. When applied to reusable protective masks made of fabric, this new coating makes it possible to maintain filtration efficiency even after numerous washing cycles, thus reducing the use of single-use masks.

2021 was a special year for Coat-X, with Japanese company OSG taking a stake in the company and the creation of a joint venture, Coat-X Japan, to directly serve the Asian market. The PECVD coating unit, commissioned in April 2022 by Coat-X Japan’s engineering team, was designed to produce Coat-X’s entire coating portfolio: Parylene-C and Parylene-F, SiO2 and multilayers of Parylene and ceramics. The Japanese electronics industry has already shown great interest in the encapsulation technology offered by Coat-X Japan and several collaborations have already been launched.

In preparing for its future, Coat-X is focusing on innovation. For example, the company is making major research efforts into new processes and materials, such as atomic layer deposition (ALD) for various oxides, such as Al2O3 or TiO2, resulting in new encapsulation solutions for new substrates and new applications.

Evelyne Gisselbrecht

DeviceMed France