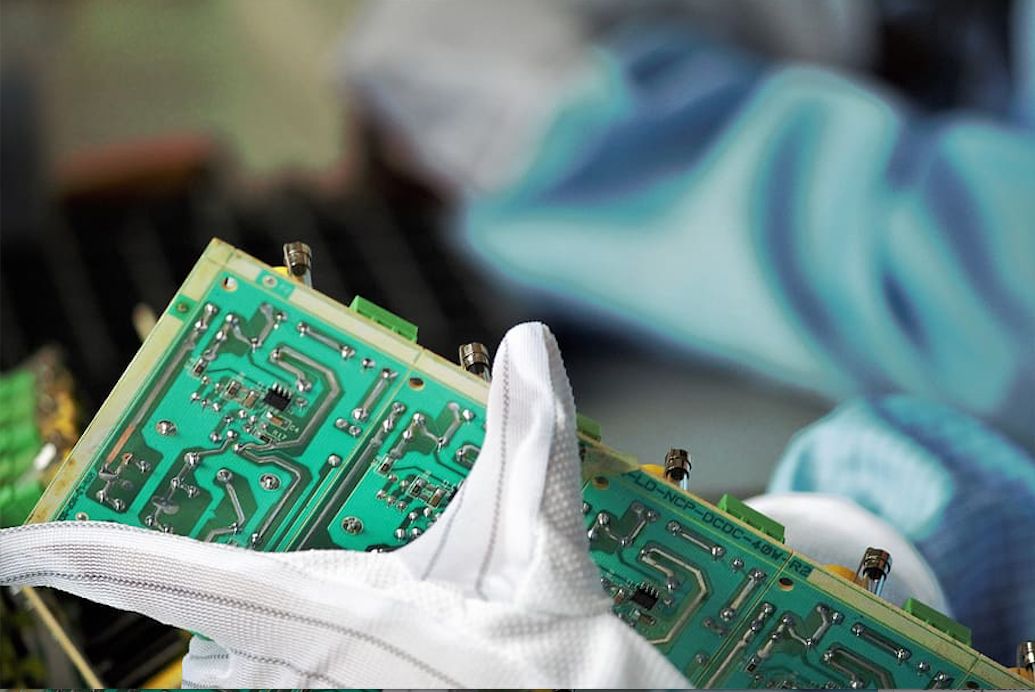

When it comes to electronics, any Swiss entity aspiring to win a contract in Europe will hear about IPC standards. Now Neuchâtel is home to the only authorised IPC Training Centre in Switzerland.

By Joël A. Grandjean

Switzerland’s first IPC Training Centre arrived right in the middle of the lockdown. While a French counterpart recently celebrated its 53rd birthday, Pierre Rogé won the right to award ICP certifications as a training centre – the first one in Switzerland. It’s been a tough road.

Electronic excellence!

More than 3,000 companies and institutions, including Boeing and Samsung, are members of IPD, a professional association created in the United States in 1957. Unlike ISO standards, which apply to companies, IPS standardises (certifies) individuals in terms of the correctness of their actions, their performance and their ability to work in accordance with good practice. Why? Because in certain applications, such as the cockpit of an airplane, on-board electronics are no laughing matter, which means it must be possible to guarantee safety, longevity and extreme reliability.

This modern take on the concept of mentoring focuses on excellence in electronics. The rules for obtaining certifications that must be renewed every two years are drawn up by people in the field, technicians and practitioners, who, working together, consult each other regularly to stay in step with developments in technologies and practices.

A reference framework that can lead to new markets

So it’s understandable that some specifiers require an IPC-certified partner before any contract can be signed. Until recently, an employee wishing to obtain any IPC certifications had to go to another country to find the nearest IPC Training Centre, but now he can simply go to Capqua, one of those companies that is the pride of Microcity in Neuchâtel, with its startup atmosphere.

Just like watchmaking co-contractors dream of winning new markets in other precision industries, such as aeronautics, automotive, space and the holy grail of medtech, so the leading lights in the electronics sector aspire to find possible openings in watchmaking. Even though watchmaking tends to focus on mechanisms, there are exceptions, such as connected objects and the armada of numerically controlled testing, quality control and innovation research equipment. This new land of opportunity comes on top of the few bits and pieces of IT that have historically been part of the industry. In other words, IPC standards have real potential.

Swiss Made label for motherboards one day?

Could the day arrive when the golden touch of small watchmaking firms starts rubbing off on electronic expertise? Here too, if you dig a little deeper, you’ll find that ICP standards come in three quality levels and that each level has its own tolerances. And since Swiss companies in this sector are pretty much first class, the communicational and operational visibility they get from obtaining ICP certification could well mean that one day, the Swiss Made label will represent value-added for motherboards.

https://capqua.ch – https://www.ipc.org/ – http://www.swi.ch/

First IPC Training Centre in Switzerland at Microcity

Founded in 1957 as the Institute of Printed Circuits, the IPC is a global association that celebrated its 60th birthday in 2017. It has more than 3,000 members, including such prestigious institutions as NASA. It has developed standards that have become benchmarks, or in some cases mandatory, for working in the transport, military, aeronautics, personal security and other industries. Surprisingly, the medical field is lagging behind, although any kind of embedded electronics in medtech would do well to take IPC standards on board, since human safety is at stake. While IPC is involved in networking and lobbying, it has also set up an education system via its approved IPC Training Centres that oversee the process leading to the awarding of IPC certifications. The first IPC Training Centre in Switzerland recently opened its doors at Microcity in Neuchâtel.

From Capqua to the first Swiss Electronics Cluster

When Pierre Rogé, a mechanical engineer, decided to strike out on his own, he set his sights on electronics. He played a role in the adventure of De Havilland Watches, a JDC Electronic brand (manufacturer of portable measuring instruments), and dabbled in the world of certification through his involvement in the Swiss Welding Institute (SWI). While there, he took part in training courses and in issuing international IPC and ESA (European Space Agency) certifications in soldering and electronic assemblies. Convinced that mastery of these disciplines deserved greater recognition, in 2021 he founded a centre of excellence aiming to bring together all electronics industry players. Founding members included the Swiss Foundation for Research in Microtechnology (FSRM) as well as the West Switzerland Electronics Group (GESO), chaired by Philippe Fischer and Olivier de Loriol, respectively.