LIGA (the German acronym for lithography, electroplating, moulding) is an additive manufacturing process used to create 3D high-aspect ratio microstructures. It can be used to fabricate complex geometries that are impossible to achieve by means of conventional manufacturing technologies. Not only does it combine low cost, rapid deployment, superb surface quality, flexible production run sizes and micrometre precision, but it is just as good as subtractive manufacturing processes. In fact, many consider it the future of miniaturisation.

There are three steps in the UV LIGA process: UV lithography, electroplating and moulding. The process starts with the fabrication of a photomask based on the component plan. The substrate is a wafer that is prepared by depositing a layer of photosensitive polymer onto it. The thickness of the layer depends on the thickness of the part to be manufactured, enabling impressive aspect ratios (for example, a 100 µm structure for a thickness of 300 µm). Following UV exposure and a solvent bath, the result is a mould that can be used for subsequent nickel deposition (electroplating).

The precision of this process depends primarily on the photomask, which can typically deliver a resolution of up to 3 μm. That’s where MultiEtch really shines: it has modified the LIGA process to enable the fabrication of extremely thin filters with guaranteed 4 µm microholes.

Developed for use by industry, this project is a high-tech and high-precision feat that is the result of three years of work to develop and advance LIGA technology. It has multiple applications in such areas as microparticle filters and analysis, diffusers, X-ray imaging and many more.

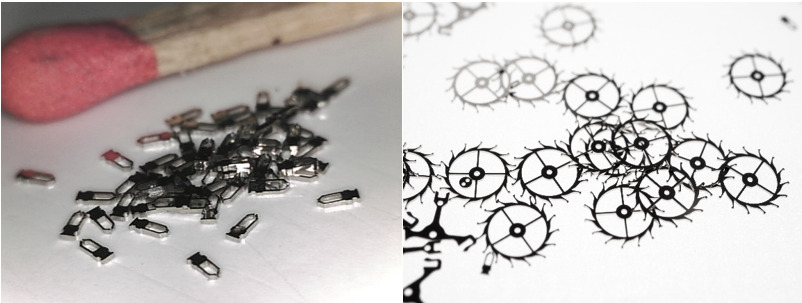

Although the company focuses mainly on chemical cutting and etching, this technology enables them to offer their services to the watch industry for a wide range of movement parts, as well as for micro-parts used in LED lighting, optical components, waveguides and even test plungers for electronics.

Lucie Layat