Imagine finding a rather heavy parcel among your post… that’s exactly what happened to some 150 CEOs in the watchmaking industry. Panatere’s campaign gave me a change to weigh up sustainable steel…

By Joël A. Grandjean

Panatere’s campaign, which was all about putting words into action, was well received. The company already has 10 years’ experience in the watchmaking and jewellery industry as well as allied sectors, such as microtechnology. It is well established as a true pioneer in sustainable solutions. The box sent to the CEOs at their homes was made of local wood and contained three steel samples. For the first time in my life, I have a chance to hold a washer made of 100% recycled steel in one hand and a piece of solar steel in the other.

The ultimate ethical luxury

Spend half a day with Raphaël Broye, founder of Panatere, a company located in the heart of Watch Valley at the very epicentre of the global watchmaking industry, and you’ll soon realise that you’re far removed from trendy marketing pitches. For several years now, he has been deploying all of his human and entrepreneurial resources to achieve a reality that is on the verge of catching up with fiction. During our interview, the ‘clean’ steel washers I hold in my hands bring to mind the organic pleasure of touching high-end bracelets made from bio-components like grape and fennel residue, for example.

What if the steel used in watchmaking and the medical industry came from special castings, not from steelmakers focused more on large volumes rather than the kinds of quantities used by the far less voracious watchmaking industry? And what if this steel – we’re talking about 4441 grade (AISI 316L) – were a recycled and recyclable material? And finally, what if 200 tonnes of this steel could come from a furnace that is not only located less than 50 km away, but is also powered by solar energy? These are not just a bunch of hypothetical questions, they are the everyday reality for Panatere, its roadmap.

A solar furnace in the Jura by 2022

Rome wasn’t built in a day! Likewise, the 100% recycled watchmaking-quality steel that Panatere is capable of producing today is the result of an effort which, after several years of research and logistical ingenuity, now accounts for some fifty tonnes of production! It is sourced from – and this is a huge leap in terms of carbon footprint – steelmakers located within a radius of 250 km. This amazing feat was made possible thanks to some 40 nearby companies that regularly deliver their steel shavings and waste. They spent years researching how to completely remove all undesirable materials such as the greases and oils used in the milling process, for example, the aim being to recast the shavings, The cycle can be repeated up to eight times without any loss of quality.

Liselotte Thuring et Raphaël Broye

That’s the first step. And since he is driven by pure conviction and fighting the odds, Raphaël Broye does not intend to stop there. Fully aware of the systemic nature of this approach, Project Leader Liselotte Thuring tell us more about this future industrial solar steel: “It took Panatere years to find the recipe for this 100% recycled 4441 grade (AISI 316L) stainless steel that can be reused once its lifecycle is over. We’re proud to be able to contribute to the local economy, combining a short-cut approach with the circular economy. Here she is alluding to the planned installation of the first solar-powered furnace right in the heart of the Swiss Jura.

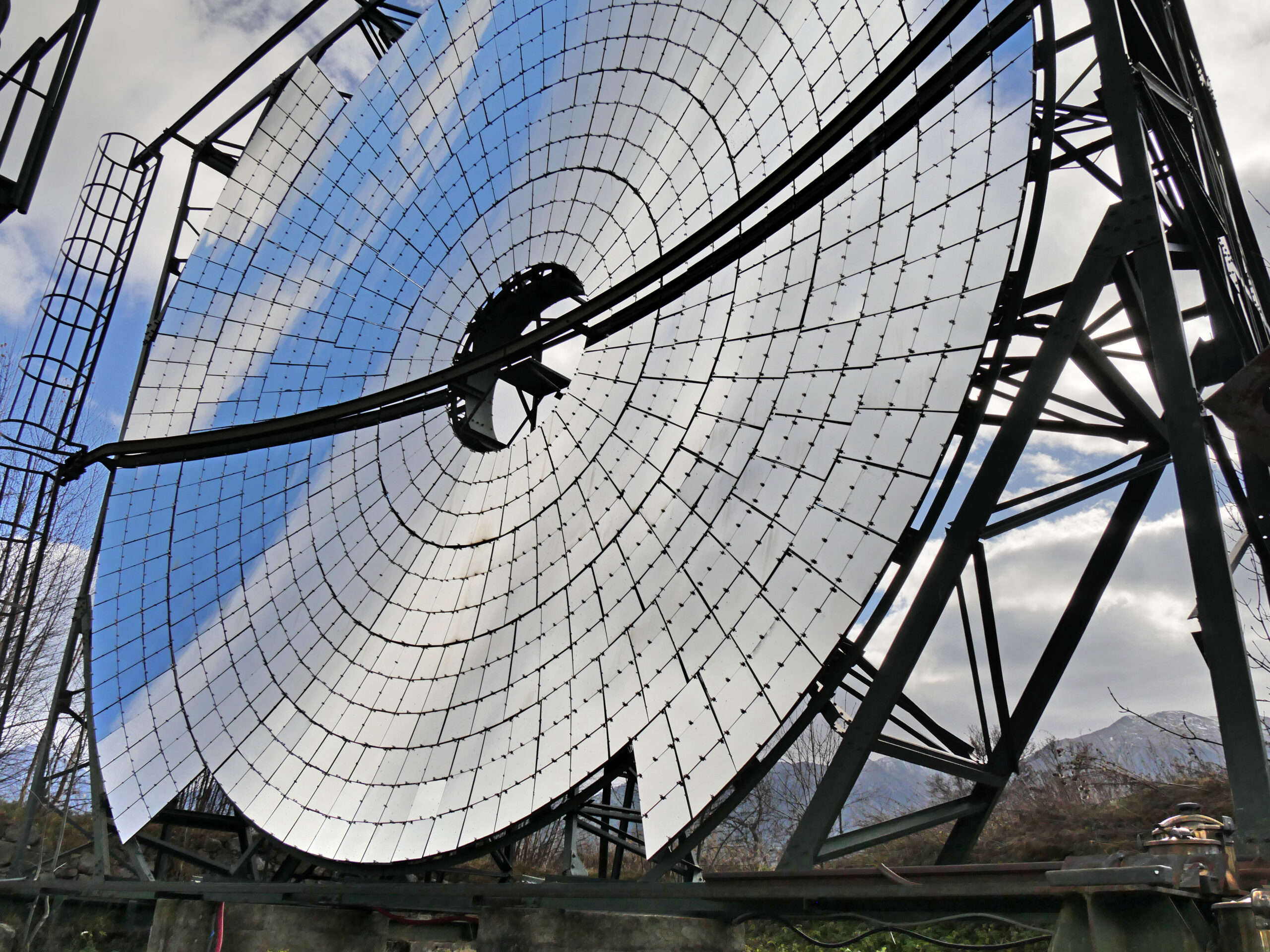

The die is cast and the race against time has begun. The research institutes and scientific experts called in to provide support can confirm: in the long run, a healthy supply for the watchmaking and medical industries, like the steel ingot Raphaël Broye hands me. He fashioned it from his 100% recycled steel using the solar furnace in Mont-Louis, aka the city of the Sun King. This is an industrial facility in the Eastern Pyrenees that has evolved into a stronghold of the French National Scientific Research Centre (CRNS).