Swiss start-up INCAPTEK invented unique dielectric materials with ultra-low dielectric constant for next-generation electronics and wireless systems. Pushing technological boundaries.

Never before were dielectrics so close to air! With the goal to revolutionise industries with novel solutions, they offer other materials with unrivalled performance, from fibre-reinforced composites and foams to unique polyimide pushing technological boundaries in many industries, from electronics, automotive and aerospace to medtech.

Unique dielectric materials

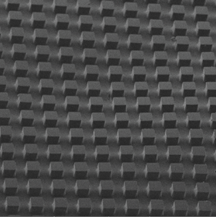

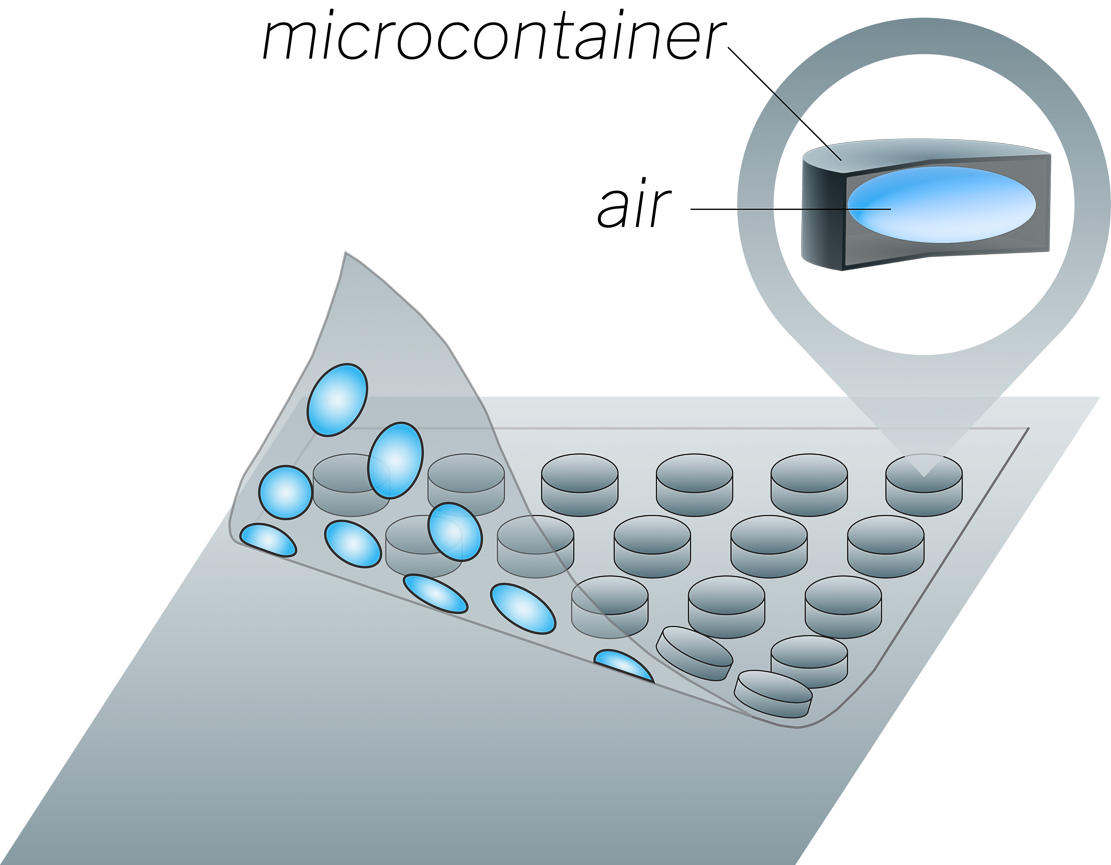

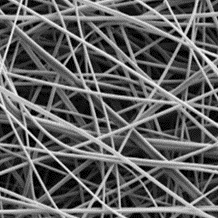

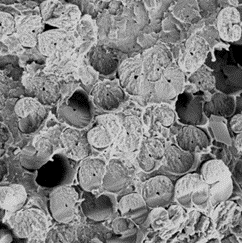

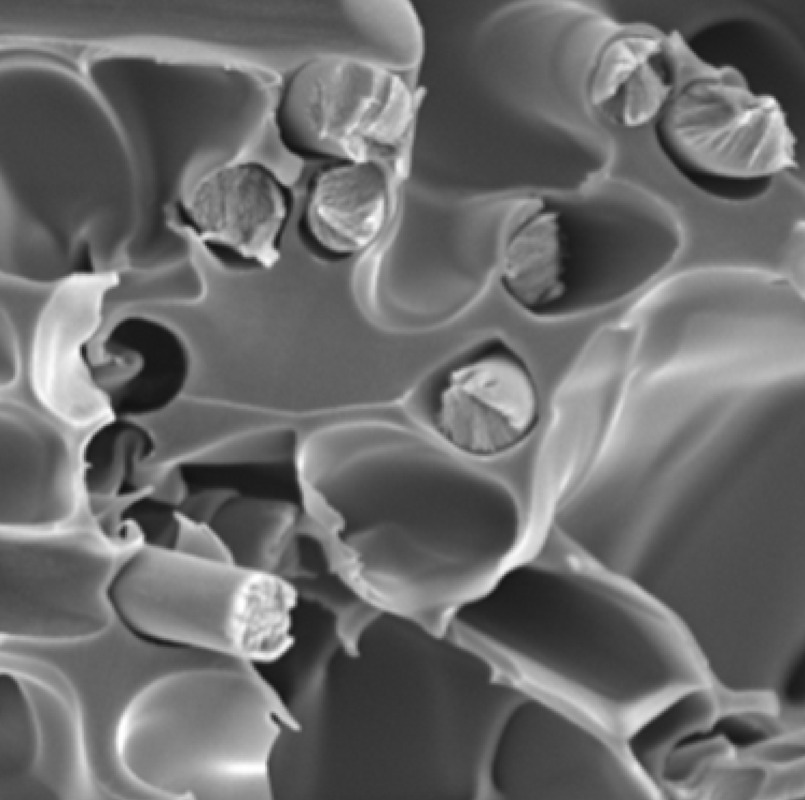

INCAPTEK designed unique dielectric materials (polyimide nanofibre non-woven fabrics, air-saturated microcontainer films and air-microcapsules) with an ultra-low dielectric constant, close to air.

Their material makes it possible to design next-generation high-frequency/high-density electronics, supercomputing and radiocommunication devices, such as 6G/next-G. They make the impossible possible.

Their technology finds many applications. For example, nanofibre non-woven fabrics can be used as lithium-ion battery separators. Surprisingly, microcontainer films, when filled with drugs, can be used as next-generation coatings for implantable medical devices to prevent infections.

Fibre-reinforced composite materials with impressive mechanical properties

Thinking outside the box, INCAPTEK also developed a cost-efficient technology to produce best-on-the-market fibre-reinforced composite materials with impressive mechanical properties for prepregs, injection moulding, and additive manufacturing. Extremely strong and durable but also ultralight, INCAPTEK’s composites are ideal construction materials for aerospace and automotive. The same technology can be also used in medtech to produce medical implants.

Fibre-reinforced composite materials

A start-up driven by innovation, established by creative scientists

Fibre-reinforced polyimide foams

INCAPTEK developed another cost-effective technology with a flexible material design to produce flame, chemical, and radiation-resistant fibre-reinforced polyimide foams with excellent insulating, thermal, and mechanical properties for aerospace and automotive industries. Due to low dielectric constant and durability, these foams can also be used for enclosing 6G/next-G radar antenna enclosure (radome) to reduce signal attenuation.

Recrystallisable polyimide

Innovation being at the core of INCAPTEK’s business, they also offer a unique-on-the-market recrystallisable polyimide (iPI) with the best-in-class combination of mechanical strength and thermal resistance for thermoplastic resins. When reinforced with carbon fibres, iPI attains a record-breaking mechanical strength with the highest maximum service temperatures for thermoplastics. Its excellent processability and compatibility with additive manufacturing and injection moulding make iPI an excellent material for high-demanding applications in aerospace, automotive, medtech and other industries.

Olga Fontanellaz

www.incaptek.com

Incaptek in brief

Start-up from Switzerland established by renowned scientists and experts in microencapsulation and material science. They develop technologies to produce best-in-class advanced materials with exceptional physicomechanical properties for various industries, from electronics, automotive and aerospace to medtech. Transforming high-performance materials into extreme-performance materials, they achieve performance beyond expectations. Not only do their materials outperform the existing products on the market, but they also make production more sustainable and cost-effective.