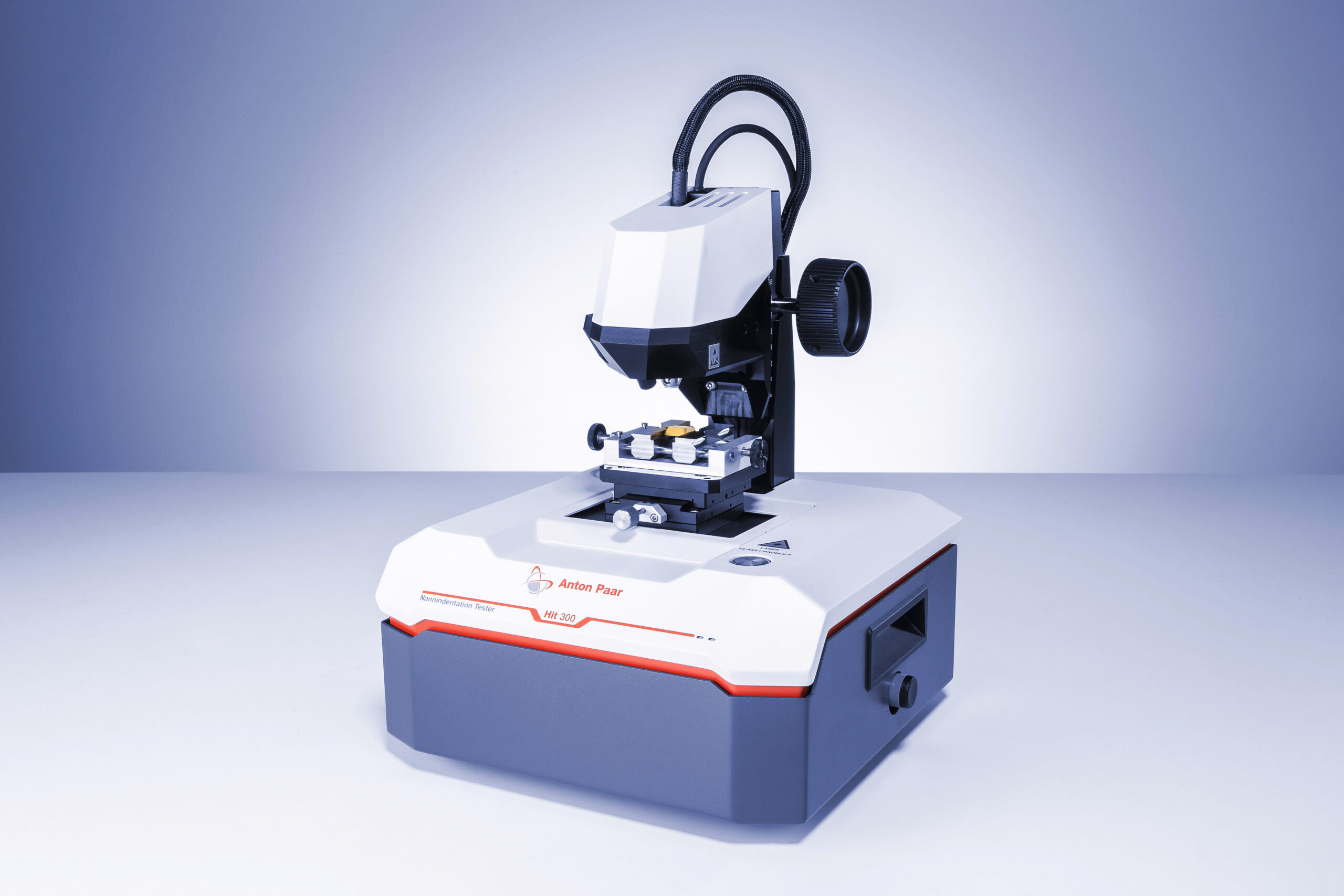

Instrumented indentation testing is a very important, sophisticated and expensive method of determining the hardness and elastic properties of a material. The Hit 300 is a high-end but very affordable nanoindentation instrument, designed for every user and every type of environment.

The simplified user interface is intuitive, the automation allows up to 600 measurements per hour and the active anti-vibration table guarantees accuracy in all environments. Start-up takes just 15 minutes, and within an hour each user is able to move from training to results on their own samples. The Hit 300 – a blend of simplicity and exquisite power.

The Hit 300 marks a new era for companies that have not yet had the opportunity to test their surfaces in-house using nanoindentation. The Hit 300 is not only extremely affordable, but also remarkably durable. Thanks to its compact size and vibration damping, it can be placed directly on the production floor. Its user-oriented design means that finished products, from the smallest to the largest, can be measured without complex preparation. A unique laser targeting system also helps the user to target the sample to an accuracy of < 1mm.

The instrument is also designed to train tomorrow’s mechanical engineers. Anton Paar

offers a teaching kit containing everything that is essential for teaching nanoindentation testing: presentations, tests, etc.

nanoindentation testing: presentations, practical tests, samples, etc.

Founded in 1922 in Graz (Austria) by Anton Paar, the company of the same name is a world leader in density and concentration measurement, the determination of dissolved carbon dioxide and in rheology and viscometry.